WELDS WELDS WELDS

Every one enjoys a little weld porn!!! We are proud of the quality of our work and believe when it comes to plain old skill as a welder, no one around can compete. We back this up by posting our welds online. This is Tig in carbon.

Carbon Tig/HeliArk

Carbon MIG

Carbon MIG

We like to make cool stands for our equipment

This is a cool base we made for our 72” belt sander. The bottom is a 1940’s heavy truck wheel found in an old field complete with old tire. The pipe was demoed from a previous project and has been outside in the elements for over 30 years. Very cool patina. Of course a nice tight fillet stick weld to hold it all together.

Stick on pipe.

This was a 6010 open root with a low-hy cap. I don’t just weld pipe, but I fit most of my own piping as well.

7018 on 150lb flange

Tig on 3" socket welds.

Tig on 3" socket welds

3" weld neck reducing flange. Open root TIG out

Boilermaker R-stamp tube test

This is a 3” schedule 160 tube test. This is a 3” pipe with a 1” hole. It is technically a combo weld, but unlike piping TIG is only used on the root. You have to go to stick on the hot pass. There are NO POWER tools allowed to take that test. Only a file and an wire hand brush. There’s over 5 pounds of stick rod in this weld which is done on the 6g. This is probably the most difficult 6g weld test in the welding world. This test is a VT and an X-ray. The tolerances are much tighter than for piping in the X-ray and the root. When this test is taken in the nuclear industry there are no inclusions allowed. The entire root has to be above flush and not to exceed 1/8” in push through. This test can also be graded with a side bend.

Boiler Maker R-stamp tube test

Oh- Did I mention that you have to use your right and left hands for this test. Unlike pipe welders, tube welders have to weld ambidextrously. Maybe 10 percent of pipe welders can use both hands. All tube welders can. Many proctors will automatically fail a candidate if they see them using just their strong arm and not switching arms. I’ve personally taken and passed this test dozens of times all across the country. I have also busted the darn thing once.

316L Tig

This is a very small weld. The part going up is only 1/2” in diameter. I made just shy of a thousand of these welds for this project. This is also 316L stainless.

Pad-Eye in stick

As a rigger certified as both NCCER advanced and OSHA Mod 4, I take rigging attachment points seriously.

Ends matter too

This was a 6000 pound piece of steel. It wasn’t exactly roll- out material. This is the opposite pad welded in the over head position. Any guy who can weld a bit can make a decent weld in a comfortable position. But a WELDER can do it in any position and smashed into the worst places.

Stick on plate

Mig

Stick on 150 lbs flange

Stick on reducer

Stick on flange

Stick fill on pipe. Ready for a cap

A good welder is a consistent welder.

Tig on 52100 tool Steel with 80s

We are the only shop in Branson that understands what it takes to properly weld specialty components and how to temper, anneal, and the appropriate pre-heats for these pieces. This piece required a hydrogen bake to anneal the metal to prevent it from fracturing as well as a specific temperature for the base metal to be at before welding. This component was part of a machine that carries people and is a critical component. Choose the right craftsman for your work.

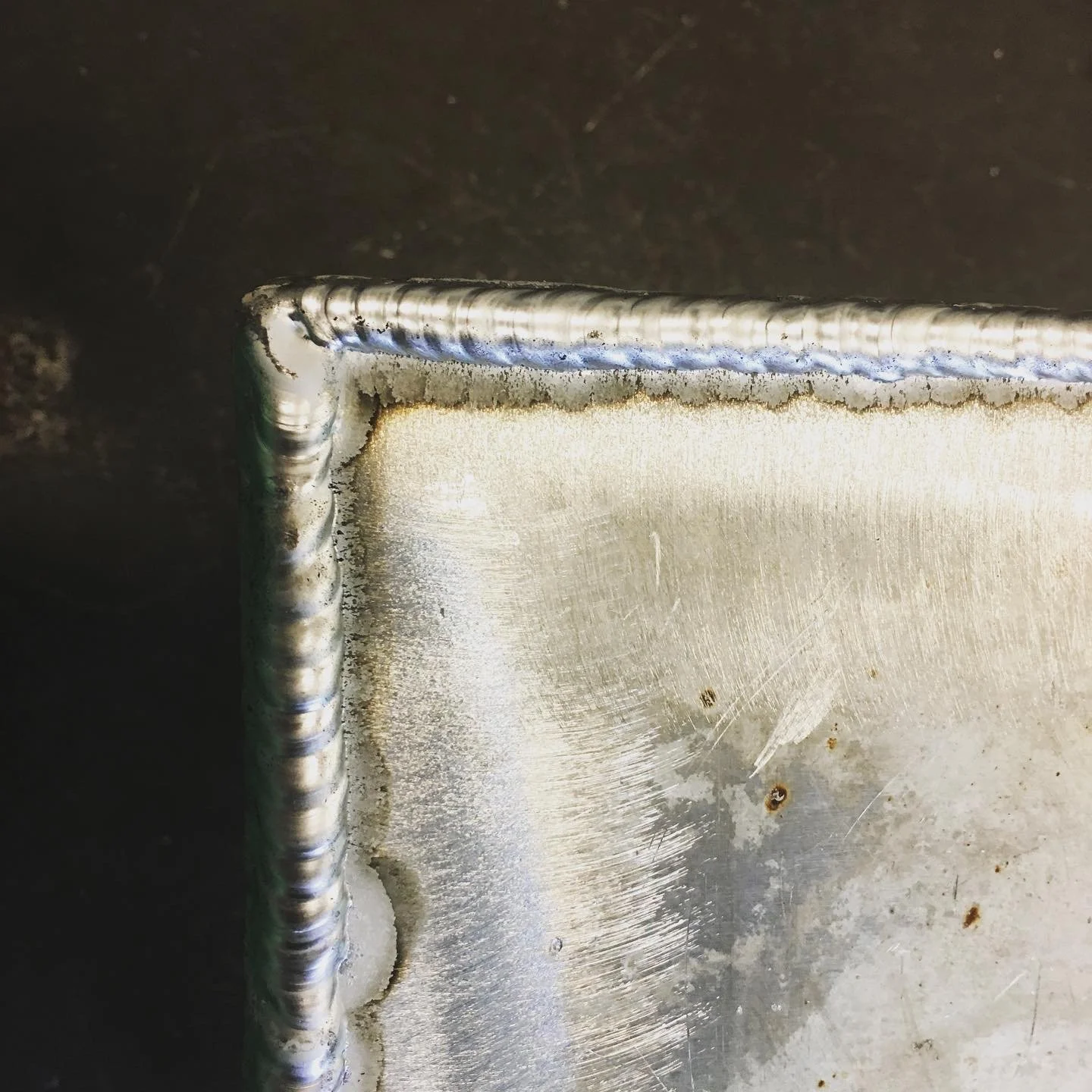

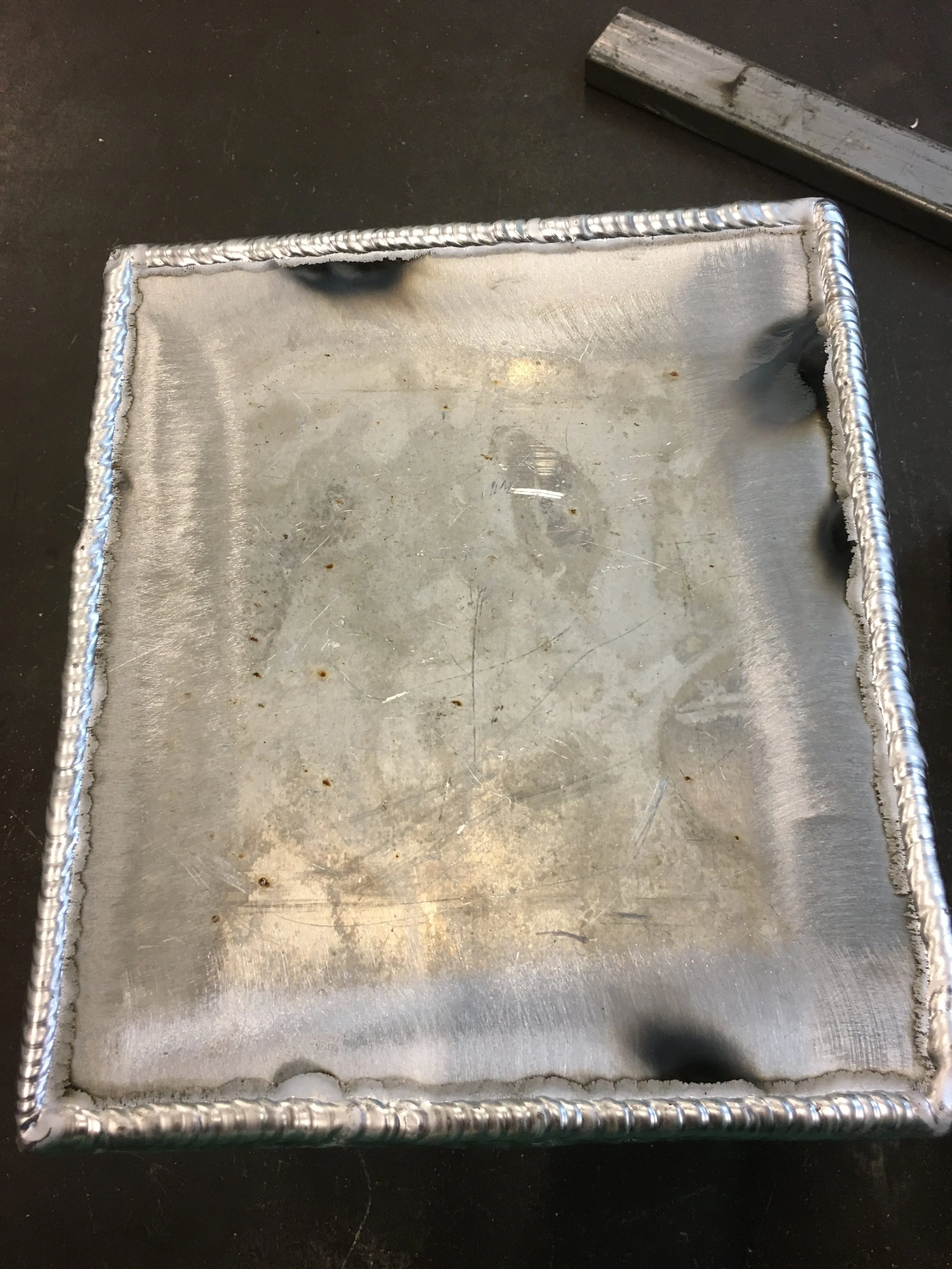

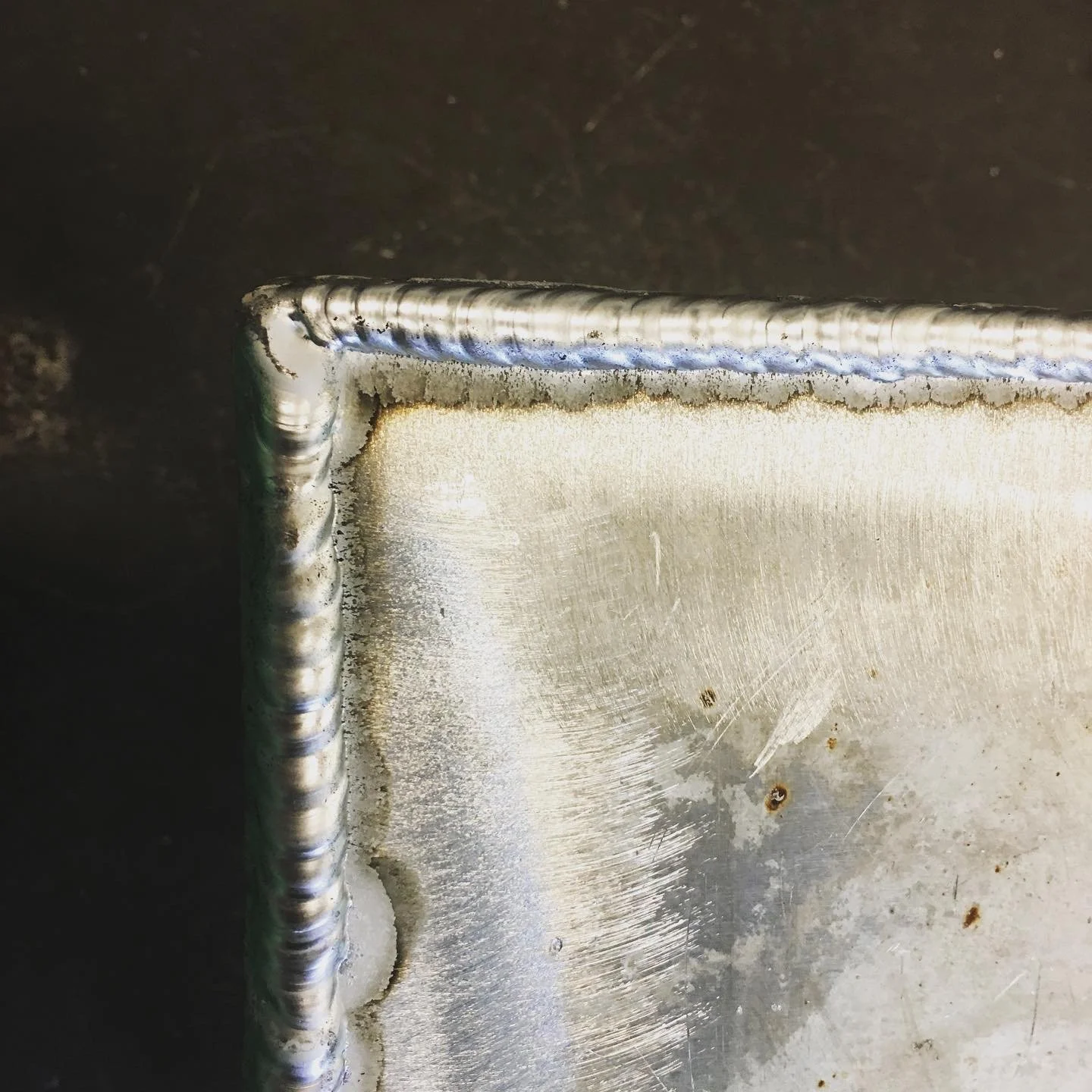

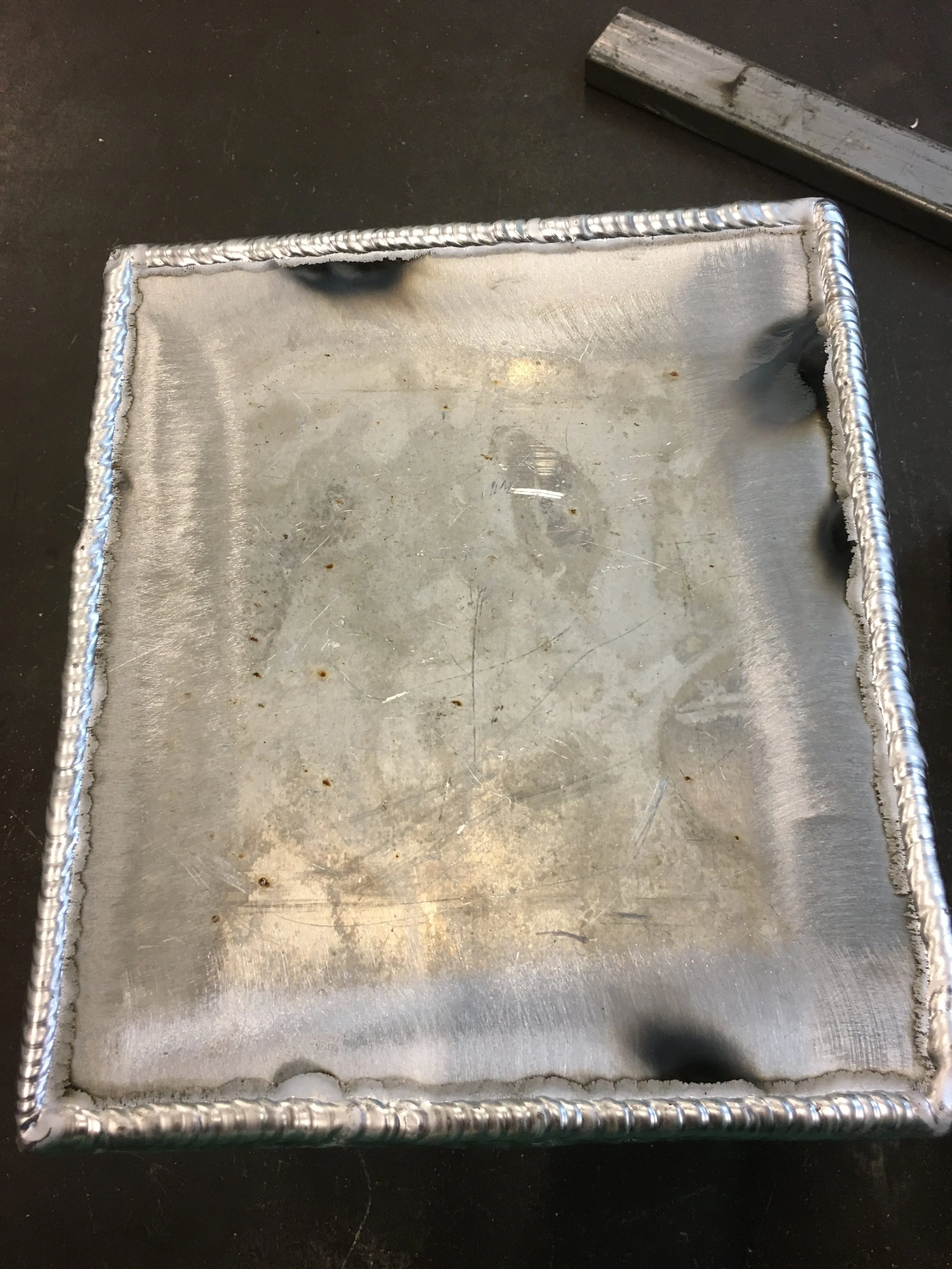

Tig on Aluminum

I’ve seen better for sure. This is my least favorite thing to do. Just one step below shooting myself in the foot. We are more than capable of handling it though and are the only shop in the area that has the expertise and equipment to TIG aluminum

TIG on aluminum

We can also MIG aluminum as well.

Stick on 308 schedule 40 Pipe

This is were you separate the wannabe’s from the real deal. This is schedule 40 308 in 8” stick all the way out including the root. It’s way faster and cheaper than TIG welding SS and doesn’t require any argon at. Tig is the industry standard because few welders have the knack for being able to do this. If you can do this- walk tall- you the man.

Carbon slip on flange on 308 SS in incolnel stick.

YES YOU CAN WELD CARBON TO SS. If you know what you are doing. This is done ghetto style with 309 ( which has enough carbon in it that it can still rust) or when it counts with Incolnel.

316 stick on pipe

Stainless Steel Soldering

This is a repair made to a commercial sink that was built from 430 stainless steel. Due to the base metal, and the location, a traditional welding solution wouldn’t of been appropriate. The sink would also of been a throw-away. However, we are able to use a low temp food grade specialty solder to repair the sink. We than electro-chemically cleaned the work area.

Soldering Brass

This was done with a specialty low temperature brass solder that has a 20.000 psi tensile strength.