Burningbird Welding mobile fab shop

This trailer lived in my mind for a couple of years till I got around to building it. It has all the tooling for pipe fabrication, structural steel fabrication and the rigging to put it where it goes. When Burningbird welding shows up to your project we are completely tooled and ready to work. I can Tig, Stick, or MIG weld out of this trailer at any time. I don’t believe in just a truck with an old machine in the back and a couple of grinders in a box.

Top View

It is not the focus of my shop to build generic trailers. If you need a basic utility trailer, we are not the people to call. I can point you in the direction of a local manufacturer who builds nothing but quality generic trailers. However, if you want something unique, or customized to satisfy a unique requirement and understand that the words “unique” and “custom” come with a unique and custom premium then Burningbird can be an option for you.

Tool box and work table in one

Everything on this trailer is built from scratch. I wanted a secure space to store all of my bulky items and double as a table to work from. Only idiots work on the ground.The wainscot idea came to me when I started on this box and I rode the theme through the whole project. I really like the effect it provided with the fenders. To me it is unique and I don’t recall seeing it elsewhere. The fenders have roughly 20 hours fab time on them. On reason is that I can’t stand butting two pieces of metal together. Every joint is a mitre. It’s stronger and looks better. It does require a little extra math and some cutting skil, hence the added time in fabrication.

Trailer Steps

Every trailer I build for myself has steps. I’m getting old and my knees aren’t what they used to be. The steps also function in stiffening the fenders. For these treads I used the expanded metal. I expect to have muddy boots climbing up and I can clean them off on the treads and not worry about mud accumulating on the treads.

Rear steps

I added these to step on when reaching down deep into the box.

Welder skid.

This box is divided inside to keep the leads separated and neatly stowed. There is some engineering to keep the box theft proof, or to discourage a thief. I believe there’s no way to completely prevent theft, you can only make them have to work at it, and if your lucky they’ll give up and walk away.

Welder skid

The welder is bolted into the skid and cannot be unbolted unless the skid is removed. The skid is bolted to the trailer. It can only be removed with a bridle hitch and a construction lift or a lift with a jib. I could of designed it to be easier to remove, but this makes it harder to steal. I can also remove this whole unit and move it onto the dually if needed.

Why the old beater truck?

I’m never asked this question when someone is next to the truck. In 2018 I found the truck in a cornfield by Sioux Falls, Iowa. It had 43000 original mile on it. The truck is the 1976 equivalent of buying an F550 today. In 2019 I spent 2 1/2 months doing a complete nut and bolt chassis restoration. I enjoy old iron and like the idea of this truck representing my business and my skill sets. I will be customizing the flatbed in the future to match the trailer.

Needing Fenders?

If you need fenders or any other trailer maintenance done, I’m more than able to satisfy your needs.

Need Fenders?

Burningbird is capable of ordering any components that your trailer might require or want. If we can’t order we’ll make it. Custom is generally better. Ordered is cheaper. Note, all of our tandem fenders have supports in the middle. We believe that you should be able to walk on your fenders. They definitely won’t fall off then and sometimes its nice to be able to step up and feel safe when you do so.

Welds

At Burningbird welding, we take WELD QUALITY seriously. Compare my welds with the welds on your trailer. Weld quality MATTERS. Only a muddobber would tell you otherwise. Undercut, LOP, porosity, and the wrong heat ALL contribute to premature failure. If you look at a fender that has fallin off, I can promise you that it had to do with weld failure or a poor weld that compromised the metal in the heat affected zone. If you want good clean work that will last, come to Burningbird.

Time

A project like this only takes a couple of hours to complete once the parts are arrived. When I put your fender on your can sit on them or stand on them. That’s a properly installed fender. We can paint or just leave it bare for you to paint yourself.

Boat Trailer

I built this trailer to match a 1456 jon boat that is a full bass boat conversion. I built this trailer to take anywhere in the country and to launch a boat anywhere that there was water. No boat launch necessary. Deep water or shallow. I can launch in Springfield lake with no issues and never get wet. There are so many custom and unique elements to this trailer that I’m comfortable with saying that I’ll never see another one like it. I has a custom made drop spindle 1 ton axle, fully boxed frame, with the wiring completely inside the wiring. The boat slides on polyethylene runners sitting on top of oak supports.

Steps and Guides

There is plenty of places to step up. The fenders and steps are integrated. When I painted the diamondplate for the steps, I impregnated the paint with sand so that there is good traction when wet. The very sold guides keep the boat centered on the trail at all times. A HUGE help in heavy wind or river current.

Fully boxed frame

The boat that rides this trailer is VERY heavy. Twin 31 deep cells up front with casting deck and tons of storage. Power anchor, rear 58 series cranking battery for the 25 horse outboard and much much more. A normal light boat trailer would crumple under the weight.

Extended removable tongue

This tongue solved a couple of problems. Make the trailer as long as possible to launch in very shallow water and to prevent theft as well as fit in the garage. The whole thing removes with the pull of a pin. When painted the treads got the same sand treatment as the steps. I can walk from the bed of the truck across water and into the boat with out betting wet.

Tilt Trailer Update

The factory latching mechanism had failed on this trailer. It had been worked on by other people, but was never done right. We have the creativity and experience to generate solutions and custom fabricate them to work. It doesn’t always work to buy something off the shelf and expect it to work.

Tilt Trailer

The owner wanted a way to lock the bed down and have it sit tight. I came up with these blocks made from 1” bar. It works quite well in getting the trailer down tight. The holes for the lock only have a 1/32” variance from the lock, so, when it’s locked down, there is zero play.

Tilt Trailer Latch

I fabbed up these new and much stouter tie downs. Everything is very tight with no movement and exponentially stronger that what the factory put on.

Tilt Trailer Tie Down Latch.

Custom Bumper for Camper

This is the original bumper. The owner wanted to be able to have a generator, Gas can, bike rack and spare tire on the bumper.

Customcamper bumper

The new bumper itself is from a thicker stronger material. The supports instead of 18ga are now 3/16 steel beam. The customers generator weighs 250 with fuel, so strength was an issue.

Custom Camper Bumper

The Generator basket is removeable.

Custom Bumper for Camper

The spare tire will bolt to the passenger side and a receiver has been installed in the middle for support the bicycle rack. The center basket is for a 5 gallon gas can.

Custom Camper Bumper

Weld quality counts.

Custom Camper Bumper

Custom 16' general purpose/car hauler

This trailer started out as the beat up carcass of a poorly homebuilt trailer.

Custom Trailer.

The floor had been completely bent down to the axles. The floor was straightened and new cross bracing installed. All of the poor welds were ground out and re-welded. Additional bracing was added through out. This is now a truly strong trailer that can handle everything the axles can.

Custom Trailer build Happy owner

New Diamond plate fenders. I add supports to all my tandem fenders so that they can be walked on. I added the expanded metal walls to the sides for looks, but also for containing small stuff. The round rod rail circumnavigating the top of the trailer is for grabbing ratchet straps every where.

Custom 16' general purpose/car hauler

I have a pet peeve of where 99% of all trailer lights are located, at the end of the trailer on the bottom. They always get damaged and they are hard to see. I always mount my lights up high. I prefer to mount license plate on the fender ( now legal in MO) with the light above it illuminating it. With this trailer, most of the wood was in decent shape. To save money we ran the old boards through a planer, only having to replace one.

Trailer Wiring

I wire my trailers with aircraft grade connections. There is no crimping. The middle is soldered together and these connections are environmentally sealed.

Custom Trailer Wiring

I make it a point to hide all of my wiring inside the trailer. If I wire a trailer, there will be no exposed wires and all connections are insulated . My goal, is in 15 years your not under your trailer trying to chase a short.

Our favorite trailer

Sharon and I wanted a little trailer to use behind our SUV’s to avoid having to drive our big trucks. We finally got around to building this and we absolutely love it. As with all of out trailers we customize for maximum use-ability and safety. We can add many of these little details to your trailer as well.

Our favorite Trailer

This trailer has a true 1 ton axle. We’ve had 1800lbs in this bad girl and she took it like a champ. Notice the two marker lights. One is actually a turn signal. We do this on all of our trailers now. We have a tie off bar wrapping the trailer on all sides. This allows you to grab a tie down any where. Notice also the bi-fold ramp.

Bi-fold trailer ramp

We make these ourselves. Its something that you never see. It has several advantages. The most obvious is greatly reduced wind resistance and increased fuel economy when towing. The difference is palpable. The way we construct this is actually significantly stronger than a 1 piece trailer ramp. There is absolutely zero flex in this ramp when it is lowered down. Instead of crappy hinges, this ramp is hinged with bearings and 1/2” bolts and can be easily removed with a wrench if needed, unlike most trailer ramps that are welded on and have to be cut free. It’s operation is very smooth.

The little things.

We also installed tie downs on all four corners that drop into the floor. These are the absolute perfect thing to use if you are trying to secure a motorcycle or something else that is top heavy. Also, on our trailers with wood decking, we take the time to cut a camphor into the decking on each side to create a pocket for the wiring to run. This hides and protects the wiring from weather, snags, and abrasions. It just looks right as well.

Wiring

This picture illustrates our attention to detail in wiring. The clear insulation goes all the way into the trailer protecting the wired for damage caused by abrasion. If you want it done cheap- we aren’t the guys. If you want it done right- bring it here.

More lights

Clearance lights are only required on trailers 16’ and larger. We don’t care. This trailer lights up like a UFO at night. The outside pair of these clearance lights are also turn signals. There is a piece of mind when you are towing, when you know that your trailer is brightly lit and other vehicles have NO DOUBT at all as to whether you’re turning, or breaking. If you get hit in a trailer that we wired, they’ll have no excuse at all. Also- NO ONE will tailgate you at night in one of our trailers. Not unless they are driving by braille to begin with.

Custom spare tire holder

Old dump trailer

The trailer is owned by a large construction company. It had received many years of hard use and abuse. The side was smashed, fenders coming off and smashed, lights didn’t work right, brakes gone and the hydraulics didn’t work right. The owner was about to sell it and buy a brand new one.

Old Dump Trailer project

For around less than half the price of a new dump trailer, we tore this down and rebuilt it. We reinforced and added a lot of details to make it better and stronger than a brand new trailer in more than one regard. The owner is blown away and thrilled by the end result. Notice the smashed in side and the silly thin lip around the top of the trailer.

Dump Trailer Rebuild

We have re-wired the battery system and installed a 7.5 amp heavy duty solar charger to the battery. These trailers tend to sit for long periods of time and are normally constructed to just charge the battery with the 7th wire of the truck. Great if the truck pulling it has the 7th wire going to the battery you drive along with it every day. The customer for this project had actually made a 30’ lead that they had to connect to the trucks battery. Now the battery is always charged and all you have to do is hit the remote. We also added a reinforced shield extending off the front of the trailer covering the battery box and tongue to protect it from dirt and debris. Note the double marker lights. One is a turn signal.

We added a holder to permanently store a small pry bar.

Pry Bar

The purpose behind the prybar is for the little pry blocks. These dump bed gates will always get bent and not shut correctly. These little tabs make it a breeze no matter how bent out of shape the doors get.

New sides

We replaced the old fenders. We are partial to squared diamond plate fenders. They just look better. The side of the trailer had been smashed in and we cut out the smashed metal and replaced it with clean. We then removed the entire top of the sides, which was just weak 14g with a pan brake and replaced it with super strong 1/4 thick steel angle. Now big rocks and debris will never dent this trailer again.

Lighting.

Once again, we re-mounted the main lights up high with the license plate on the fender. The housings are 1/4” steel and the lights are completely protected. We like large LED lights. The five clearance lights also act as turn signals as well. Bright at night is an understatement for this trailer.

Proper wiring

We prefer to use junction boxes when wiring 7 wire trailers. Also, on a dump trailer, its more difficult to hide the wiring so we wrap it all up in a corrugated pvc loom for protection.

Car hauler modification

This is the before image. The customer bought a new 24’ car hauler and wanted to have a detachable winch installed.

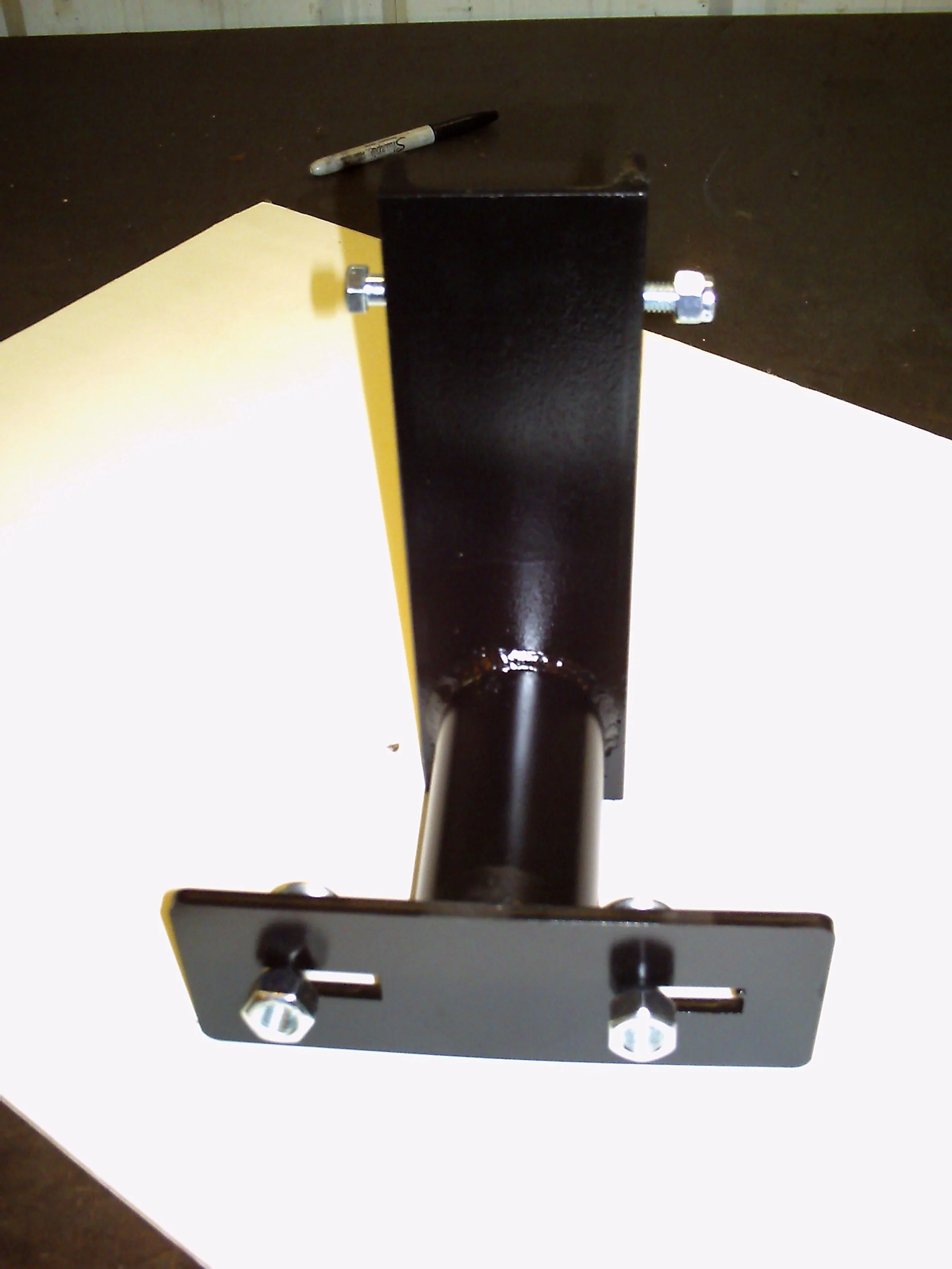

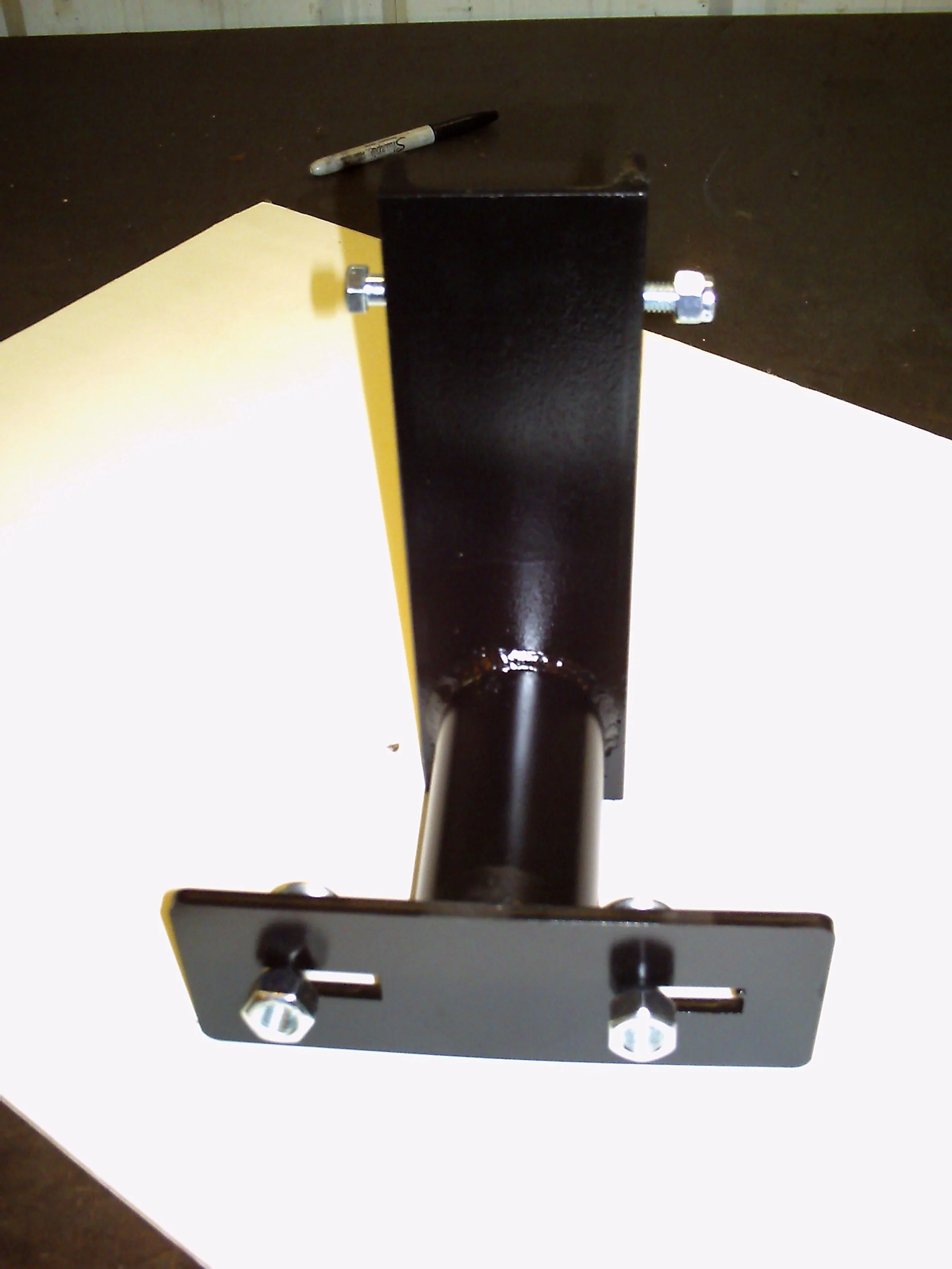

Car hauler modification

This the the mount for the detachable winch. The winch itself had a mounting bracket it was bolted onto and simply slid into the receiver.

Car Hauler Modification

Here is the whole shebang assembled. The winch easily released. The customer had a plug installed into the bumper of their truck to power the winch straight off of the trucks batteries removing the need for a permanent battery.

Food Trailer

The owner of this food trailer had a couple of things done. They needed lockable enclosed storage for a generator on the tongue of the trailer as well as Stainless Steel splash guards all around the cooking area. Their very good food is fried in large woks and they were concerned about bystander getting hot oil on them by accident.

Food Trailer Stainless splash guards.

Here they are completed. We didn’t just cut some sheets and screw them in. The pieces are reinforced so that they are rigid an do not flop around in the wind or when traveling. The operation of the ramp on the back was not affected.

Raised Jack

I don’t remember why the customer wanted this done. But we did it.

Simple things

Most trailer manufactures put just enough support on a fender to keep it from falling off going down the road. This trailer was in for something else and we also reinforced the fenders as they were coming loose. This is our preferred method as well as a middle support for tandem axles.

The little things

Let us help you make the little improvements that make your trailer work smoother and easier. Trailer builders simply want to build as quick and cheap as possible. A lot of time what you have “works” but could definitely be improved. The little rings are a great example.