We come prepared!

Most guys work out of a little trailer. For general construction we have a huge box truck filled with all the tools, equipment and hardware for any general construction project. The inside of this truck is completely built out to be a total moving work shop.

Steel Work

For metal only work we have a custom built fab trailer. We can fit pipe, structural steel or anything you can imagine off of this trailer. Who built the trailer? We did. We’re more than a guy just driving around with a welder in the back of his truck and a couple of grinders. You may have heard our ‘76 around town lately. The old girl is actually a complete chassis restoration with all the goodies. Built fuel injected 390 FE , 4:56 gears, fuel tank from a Kenworth semi-truck and all LED lighting. She’s our favorite truck of our fleet and everyone loves driving her. This was a shot taken while performing work at Top of the Rock in Ridgedale.

Dumpster Gate

Finished look.

Dumpster Gate

We designed and fabricated this dumpster gate.

Lamp Post Base Plate

Pretty Welds

Mirror Welding

This is myself preparing to make a 6010 open root mirror weld. There was around an inch of space between the column and a steel structure inside the building. This was done with a 6010 root and 7018 fill and cap.

New Steel

At this point the structure has been raised 3” to original elevation. All the columns have been replaced. New beams have been installed. Appropriate coatings have been applied to the metal. All of the Joist have been jacked up to the proper elevation and hangered into the back of the beams as well as being appropriately blocked.

Carpentry as well as metal work

Burningbird welding also has a wealth of knowledge in carpentry, framing and general construction. We should be your first call when dealing with integrated structures. All of the joists in this picture had to be raised. If we can’t do the project right, with proper connections and ensuring everything is tied in properly, we won’t do it.

Better than before

Burningbird Welding functions with the philosophy of “ Better than before”. We removed all of the old siding and than resided the south side of this structure as well as re-designed better guttering. The structure was also painted as well as the columns. While we are not a siding contractor, we are are more than capable of doing this work within the scope of our own projects.

Before

The bases of all of these columns had deteriorated severely due to being buried in dirt by a previous owner. The bottoms of the columns had to be completely replaced. The challenge is how to support the structure while performing the work and ensuring that every column returns to the exact same elevation to support the structure.

Innovative Solutions

Burningbird Welding has a long history of solving problems and coming up with innovative solutions. There were 30 columns on this project that had to have the bottoms replaced and the footings remediated. As certified riggers with 15 years of worldwide experience in industrial rigging, Burningbird Welding can find a solution to your conundrum. This jacking collar system was designed and fabricated in house in order to lift each column individually, perform the needed work, than return to original elevation. Our innovative solution allowed the business to stay open the entire time of the remediation.

Proper welding

We are certified to weld pipe and column steel with an open root in either TIG or Stick. If you hire a local contractor to perform this kind of work, ensure that they are properly certified and have the experience. We have years of experience and have performed this kind of weld hundreds of times.

Bollards

Yes we do bollards. We can perform just the metal work, or we can provide all of the excavation, drilling and concrete work needed to properly install bollards.

Bollards

Bollards done right. These bollards are all welded and still filled with concrete. The 2x2 post for signage coming out is set in concrete as well. Burningbird Welding does things differently than the other guys. We have specially built equipment that allows us to weld on round surfaces and than smooth the surface to where the weld line disappears. We also prefer to use weld on caps for a much cleaner appearance than the traditional concrete top shaped with a shopping bag. This process takes longer but the quality of the finish is undeniable.

Big Fans way up in the air.

This was a project involving the installation of 72” industrial fans roughly 30’ in the air. We opened up the building, installed the louvres and used rigging to set the fans appropriately.

Proper installation

We fabricated brackets to lock the bottom of the fan tight against the wall. We than fabricated the bracket that you see in order to use all threads with hillside washers to physically ratchet the fan tight against the wall. Notice the all thread in the middle. These fans are heavy. It was important to us to spread the load out. We were able to transfer the weight of each fan to 3 purlins instead of just the one on the bottom. It’s attention to detail like this that will ensure these are in service as long as the building is there.

Coolest bathroom in town

We have a wide skill set. We designed this bathroom and fabricated all of the components in our shop. The room itself is a frame out where we cut the building open and framed in the space. This is an example of a project that where we can function as a GC and coordinate all the sub contractors needed. The bathroom stall door is on rollers.

Sink

This sink is ADA compliant and has passed inspection. We designed and built the steel structure supporting the counter top. We also poured the concrete countertop ourselves. We have the capability of designing a piece on the computer in 2d as well as 3d to not only see what it will look like, but to allow our customer to understand our concept.

Urinal Dividers

Pretty cool huh? We designed and fabricated these urinal dividers. That is actual copper, not paint.

Before we started.

This is a before image.

Columns and Beams

There were a total of 11 steel columns on new footings. Every column had its own specific elevation for the roof to flow symmetrically.

Here is the finished product.

This was a complicated project. The porch is shaped like an isosceles triangle. Without any hips means that none of the beams are flat and all have an angle. The front 6x16” Dougfir beam sits on 1.8 degrees of drop. We performed the final engineering and fabrication of ever part of this project.

Framing

Yes!! We can frame. It’s fun to do from time to time as well. With our partners we can offer complete construction from breaking the dirt and concrete to framing to finish work.

Big porch

This porch was over built to support a hot tub!

Top of the Rock Christmas Tree

We can provide complete rigging and structural steel support. This is a project we did, with crane support from Branson Crane. With the proper planning we were able perform the complete assembly of this 40,000 lbs Christmas Tree in just 12 hours at night.

It's taller than you think......

Night rigging is especially dangerous. We have years of experience and education to allow us to design a lift and initiate it at night safely and efficiently.

What goes up......

We were back in the spring to disassemble the entire structure and transport it to another property for storage. We took down all of the lighting and packaged it for shipping back to Florida as well as coordinating the entire project for the GC, Tideline Construction out of Florida.

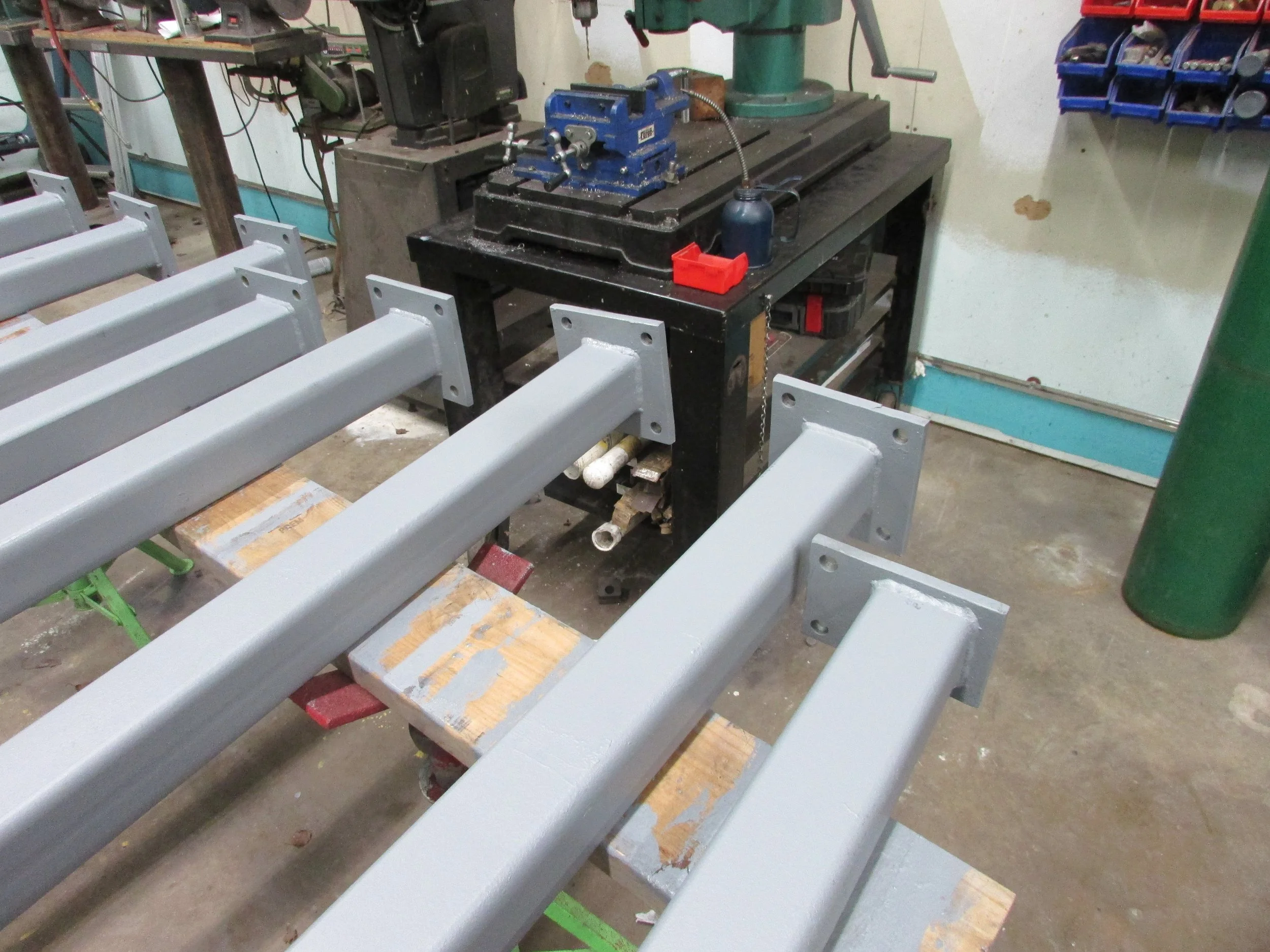

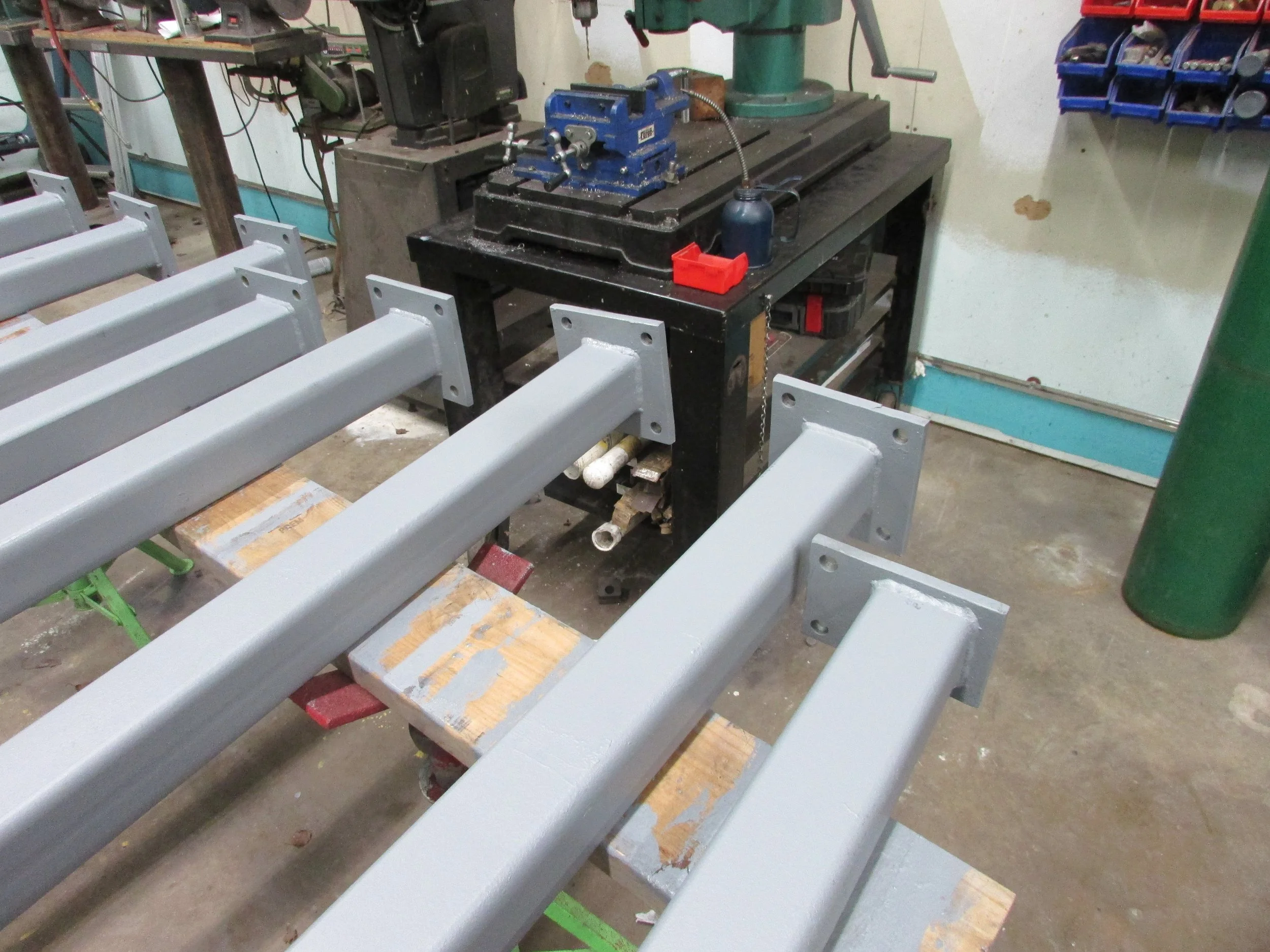

Steel Package

This package is for a 15 thousand square foot building. We took the project from rough drawings to detailing , blue printing, fabrication, inspection and than erection. We also coordinated with the concrete contractor and provided all of their layout information. This project had 39 columns and many beams.

Steel Building Fabrication and Welding

We are able to take your simple bid drawings, and have them engineered to a complete total fabrication package. The welding speaks for itself.

Steel and Wood Integration

Framing and Steel Erection

We are experts at integrating materials.

Commercial Stairs

Talk to us about your new construction projects.

Structural Steels and pan decking

Framing

We designed this project. 16’ walls on a slab. We handled the project from design- dirt work- concrete- and than framing.

16' tall framing

Framed and finished

Aluminum Bridge

We like the unusual. We took this project from rough architectural drawings through engineering, detailing, fabrication and than installation. Those are the largest aluminum C-channels available in the country.

Industrial Platform Handrailing

How do you do this?

This is the sub-frame for the mask in the next picture. We did one for the Titanic in Pigeon Forge as well. Native Signs provided the mask and the installation on this project.

Steel Package

This was a project in a local hotel. The steel shown is underneath the concrete. We had to remove the concrete, install the steel, and pour all new again. Thanks to Weber Masonry and Concrete for a great pour.

Foot Pegs

We were happy to help the folks at TRACK properly install the pegs all the way to the top of this tower.

Pre-Cast Work

This was a substantial Project. The walls are pre-cast concrete. We took the engineers specifications for steel re-enforcement and designed these supports. After the installation, we than cut out the window and the doorway.